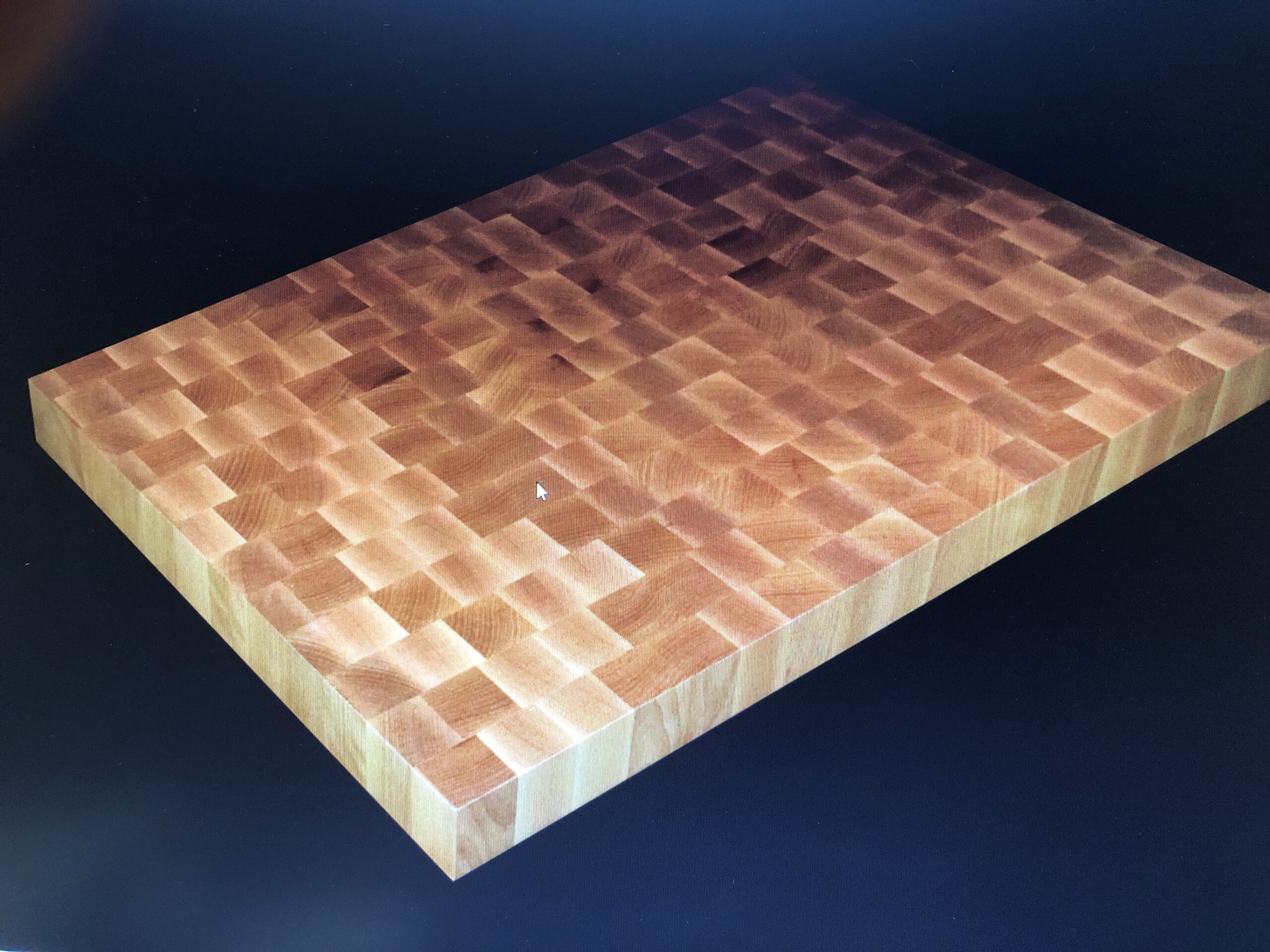

Maple End Grain Countertop

Project Details

We were approached by a client looking for an End Grain Countertop for their newly remodeled kitchen. They wanted this focal piece made out of Maple. This wood countertop would separate their kitchen from their dining area.

As we worked very closely together to achieve their inspiration, we worked diligently in the shop to create their dream countertop.

This project was very tedious in each block was made from 1-1/2″x1-1/2″ square blocks. These were milled to each size, then glued up into sections. Once they were glued up they were then milled running through the planer to achieve a smooth surface. Any rough sections were then carefully sanded by piece.

After each section was made into the blocks they were then glued up into larger sections. The same process was then followed by each step multiple times till it was large enough to run through the planer again. This process happened roughly 4 times to achieve the final countertop width.

Maple End Grain Countertop

Project Details continued

Once the countertop achieved its final width it was slightly larger in size to run the entire countertop through the planer.

The next process took a few days of sanding all the rough ends, edges and uneven areas where the final pieces were glued up to one another. When doing these projects it is imperative you have the proper weather to work with as wood can expand and contract depending on the climate.

Most woods are easier to work with in warmer climates as it is dryer air. Once the sanding was complete a mineral oil was added to the countertop to help seal the wood. This process helps protect the wood over time and prolong its lifespan.

We were eager to get this project finished in time as the customer had family coming in town for the holidays. They were very pleased with the final product!